Machinery

Assembly & Welding

We are specialized on manufacturing welded products. Our welder`s are qualified and welding is based on Welding Procedure Specifications. We have WPS`s for numerous different materials and new WPS`s will be made if needed. Our welding fabrication is based on certified ISO3834-2 quality system of welding.

We weld structural, pressure vessel, heat and fire proof, stainless, acid proof and duplex steels. Over the years we have gathered lots of information on material behaviour during the welding so we are able to manufacture quite demanding welded structures.

Our welding production is mainly MIG/MAG-, TIG or SMAW manual welding. We have also longitude welding machine (12m) and submerged arc welding machine. Our newest acquisition is a welding cobot.

Heat treatment can be done in our facilities for most of the products. Larger structures can be heat treated in same town.

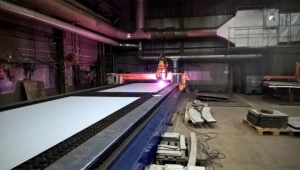

Laser and plasma cutting

Cutting of plate parts can be done with laser or plasma cutting. Laser suits exceptionally with cutting of thin plates and with plasma we can cut parts up to 30mm. Plasma machine is equipped with bewel cutting head so welding chamfer`s can be made easily. Fe and stainless steel material qualities can be cut with plasma.

If part`s shapes are simple then we can cut parts with plate shear. With our machine we can cut plates around 8mm depending of material hardness.

We have structural, pressure vessel, heat and fire proof, stainless, acid proof and duplex steels in our storage. Every material have material certificate. Special materials will be looked out case-by-case.

- 10kW

- cutting area 2000 x 6000mm

- cutting ability SS-materials to 20mm and Fe-materials to 25mm

- my. 2021

- continuous cutting 32mm

- max cutting thickness 64mm

- bevel cutting +/- 50°

- cutting table 2500 x 12000mm

- my.2023

- working length 3000mm

- plate thickness max. 6-10mm

- my.1999

Bending & rolling

We have three hydraulic and one servomotor press brakes. With the most sturdiest 1000tn machine we can bend six meter long pieces.

Plate rounding can be done with three plate mangles. With bigger machine it is possible to be bend three meters wide plates.

In addition, we have section bending machine for profiles and hydraulic press.

- working length 6m

- bending force 1000t

- upper tool: Gooseneck and R6, R10 and R20 punch tips

- my. 2014

- working length 4,2m

- bending force 400t

- my.1999

- working length 1320mm

- bending force 100t

- servo electric drive system

- superior accuracy

- my.2023

- working length 3,7m

- bending force 200t

- lots of special tools

- working length 3000mm

- rolling thickness 20mm

- pre-bending thickness 16mm

- my.2007

- working length 1600mm

- 4 – rolls

- NC Playback control system

- my.2020

- plate roller

- section bending machine

- hydraulic press, 200tn

Sawing

Cutting of bar materials can be done with NC-bandsaw that can saw profiles up to 335x500mm. Saw is equipped with 2,3 meters long automatic feeding table. Length of material loading and unloading tables is around 12 meters.

- fully automatic bandsaw

- cutting capacity max 335 x 500mm

- hydraulic bundle sawing equipment

- automatic detection of piece`s zero line

- cutting angle +/-30°

- automatic feeding table 2,3m

- feeding table length 12m+

- my.2016

Machining

We have around ten different machines of which we can use for machining of parts.

- max turning ɸ500mm

- max turning length 1700mm

- thru spindle ɸ165mm

- feeding table length 12m+

- my.2011

- max turning ɸ510mm

- max turning length 750mm

- thru spindle ɸ115mm

- feeding table length 9m+

- my.2007

- piece`s maximum ɸ ca. 5000mm

- piece`s maximum height ca. 2000mm

- NC-machine

- X = 5000mm, Y = 1000mm, Z = 800mm

- table size 900 x 5000mm

- load capacity 5000kg

- X = 2230mm, Y = 1450mm, Z = 700mm

- table size 1250 x 2000mm

- load capacity 6000kg

- X = 1020mm, Y = 540mm, Z = 540mm

- load capacity 700kg

- my.2013

- Manual Lathes, 2pcs

- Radial Drilling Machines, 2pcs

- Universal Milling Machine

Surface treatment and packing

Surface treatment can be performed in our own facilities. Parts can be treated with shot blasting (Fe-materials) or aluminium blasting (SS –materials) and after that be wet painted.

Dimensions of the facility:

- Length 13m

- Width 6m

- Height 5,5m

Dimensions of the facility:

- Length 8m

- Width 4,5m

- Height, 4,5m

Dimensions of the facility:

- Length 34m

- Width 12m

- Height 5,5m

Dimensions of the facility:

- Length 20m

- Width 12m

- Height 5,5m